Weber Upgrades

automate existing production lines

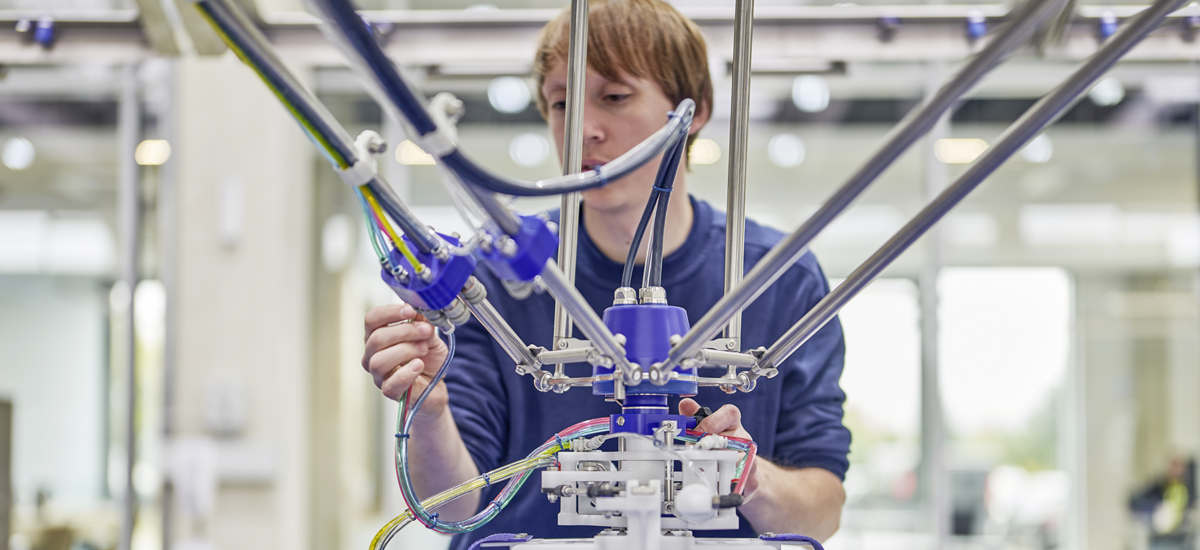

Optimizing the performance and increasing the quality of your existing production lines? Weber upgrades make it possible! With our automation solutions you raise your technology in terms of performance and hygiene to a new level. That is sustainable and economical – and allows you to stay up-to-date and grow with a manageable investment.

Your production can do more!

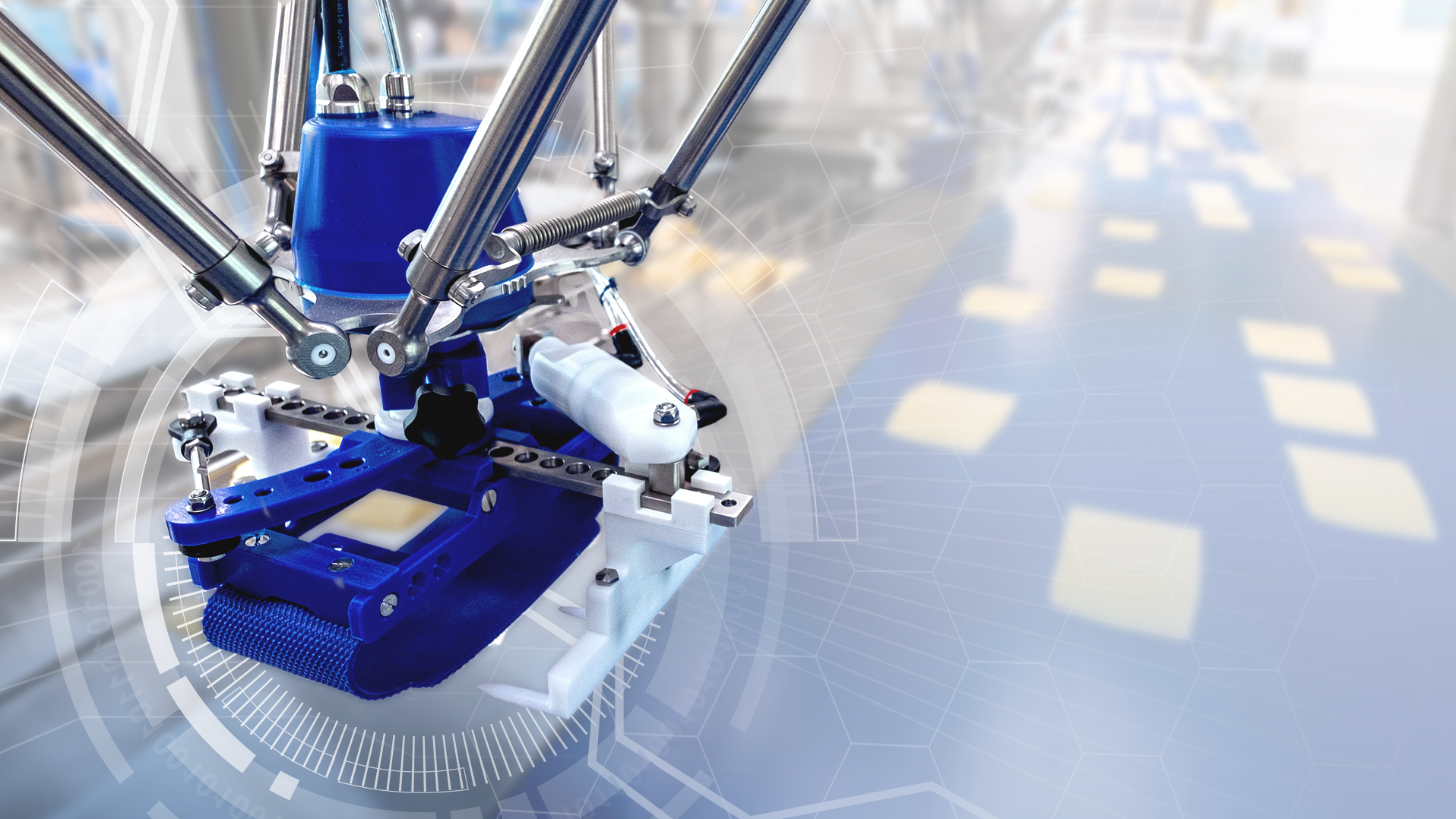

By retrofitting automation components, existing lines will be prepared perfectly for future demands. Whether it is an automatic feeder or a highly flexible pick robot: take advantage of the many options offered by Weber upgrades and take your sausage or cheese production to a new level!

Advantages

- Realization of multi-type and multi-layer packs in the smallest of spaces

(overlapping, 90 ° rotation, variable portion shapes) - Processing of all common portion shapes and sizes

- Fully automatic position correction

- Gripper with quick-change device

- High flexibility, reduced labor costs, quick cleaning

- Completely filling out the package for overlapped portions

- No human interfering required

- Maximum hygiene and food safety

- Number of tracks and layers variable

Advantages

- Modular, scalable system

- All in one: Creates format sets, buffers and loads them

- Various configurations available - from basic to fully equipped

- Compact, small footprint

- Easy cleaning, optimal access to the packaging machine

- Easy maintenance, easy service

- Loading conveyor can be folded and swiveled sideways

Contact us now!

Our upgrade advisor will be in touch with you. We are looking forward to your message!